|

I am not particularly good at the key skill that every architectural firm must have - SELLING. You might have the same problem that I do. I have always had to wear too many hats, and one of those other hats always seemed to 'need me' more than sales. Being an introvert doesn't help either. Nevertheless, I have learned tons about how you are supposed to do it; and I have a pretty good track record when it's crunch time. My preferred strategy, which happens to fit my personality, is to:

One of our largest projects was a private high school that took 7 years to get to the point of getting hired. Then, I helped the Owner put together an RFP process to meet oversight requirements. Needless to say, with what I had learned about them and the project in 7 years, we were the obvious choice - even over a couple of alums. There Isn't Any One Way To Go About Sales How tall does a sign need to be to be readable from a mile away? I needed to know that because a regional airline we were designing a hangar for wanted a sign readable from the terminal across the airfield. Luckily hangars are big. We needed a spot that would accommodate a 25' long x 12' high 6-letter logo - 'Comair'. Font Size vs Distance I had been vaguely aware of the relationship between font size and distance. I knew from past experience that 10" letters worked well on schools, but that was about it. I think I found a rule of thumb in Graphic Standards; and, once we had a graphic, we verified the suitability with the sign manufacturer. Signage Rules Of Thumb Architects and Facebook I have bitten off more than I can chew. The truth is that I usually figure out how something should work after I have been doing it for six months. I am going to take a hiatus on publishing the NEWSletter until I can figure out the big picture.

Everyone's heard of AIA Documents. I just saw this ad in a magazine and wondered what the buzz was all about. They are now a browser-based resource rather than a computer-based tool. So you can be anywhere when you work on their contracts and forms.

I think AIA Documents do a good job for all parties, and they have a good reputation as an industry standard. These days they are very easy to use, and the browser-based aspect is very nice. The other thing about AIA Documents is that they cover way more types of situations than you can ever do justice to - all types of construction contracts, change orders, BIM, sustainability, and on and on. There are 180 documents. Many of them would appeal to non-architect design professionals, too. I think they are especially good for public projects. If you get into a legal shoot-out, you don't want to be 'armed' with your home made documents. So how do you get them and how do you use them? Back in the day, you bought them from your blueprinter or the local AIA office; then you filled them out with a typewriter. That was only slightly easier than stone tablets and chisels. Now, as I mentioned above, the AIA Documents are browser-based. In a nutshell:

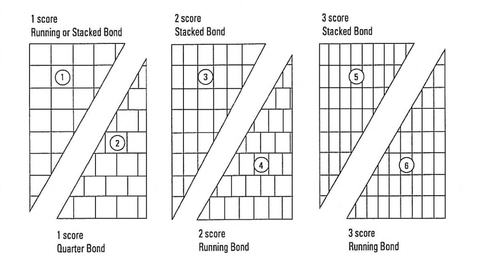

The service is kind of pricey but there are buying options. And under the terms of an AIA Agreement, the cost of these forms for bidding or construction would normally be a reimbursable expense! At least with the unlimited licenses, maybe the individual document service too, you can save standard clauses for re-use. Here are the purchasing options from most to least expensive. The cost for AIA members would be less. Block bond doesn't seem like something that needs much thought, but there are a couple of things to consider. Running bond is usually the assumed coursing bond and is the most common solution. Stacked bond is less utilitarian in appearance and the most used alternative.

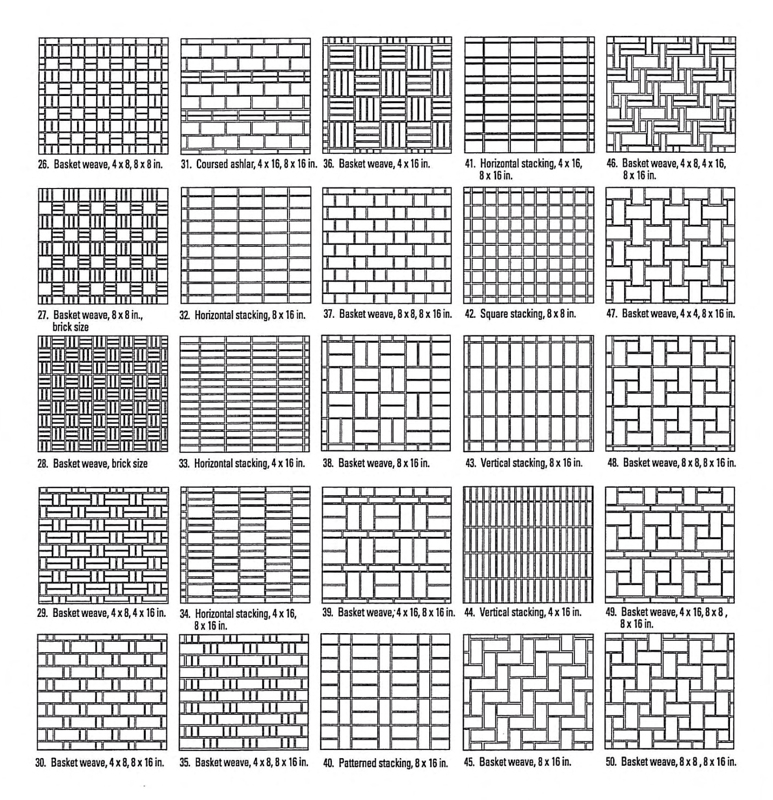

A more tile-like appearance can be gotten from scored block, which reduces the apparent scale of the standard 16x8 block face. It makes a big difference in appearance and adds very little in cost. The single score block is pretty standard. Double and triple scores are possible with a special order. This gives you a choice of 8x8, 5.33x8, and 4x8. It’s also possible to use various sizes of block to get a more un-block-like appearance, something more like stonework. One caveat, if the wall is load-bearing or quite tall it may need grouted reinforcing in the cells of the block. The cells need to line up to allow the placement of the reinforcing. Many of these bond patterns do not have aligned cells that will accommodate the reinforcing. Below are 50 patterns that you can create with standard sized block. As you can see, there are many ways to add interest to an otherwise utilitarian material. These graphics come from the Reading Rock Block Catalog, which is a very handy reference. Some Random Thoughts On Time Management:

THE WORK DAY The 8-5 work day is quickly becoming an anachronism. It is still meaningful for a lot of workers, but not for knowledge workers, designers for instance. Being at the office is only good for making it look like something is getting done. When you factor in all the gossip, 'doing office stuff', interruptions, 'having a meeting' events and times when you really don't feel like working, the typical work day is maybe 5 hours of actual work. Maybe. I think it would be more adult-like for everyone to work 35 productive hours a week when and where they want to work them. COMP TIME Compensatory Time is a tool for recognizing and documenting actual hours worked. If the goal is 35 hours of productive work a week, and you actually worked 30 or 40 hours, then the 5 hour difference is tracked as a running balance. Periodically you evaluate whether any action should be taken. A big balance might merit a bonus. A deficit might require a conversation, or it might show that the work is getting done just fine without all the hours. It is basically a salary tool to make sure neither party is being taken advantage of. OFFICE HOURS / BEING AT THE OFFICE The reality is that knowledge workers don't have many reasons to be at the office. Office hours let the letter carrier and sales reps know when they can expect to find someone in the office. Everyone else communicates by phone or email. So set the goal of manning the office from 10 AM to 3 PM. Post a sign. Coordinate schedules to meet the 10 - 3 goal; and let everyone work at the office when they want to. SCHOOL HABITS / OUTGROW OR HONOR? I know I taught myself some lousy time-management habits when I was in school. I wouldn't be surprised if you did, too. If those habits don't work for you, by all means change them. But if those habits represent who you are and how you deal with time, then I think it is alright to decide to honor the habits and not change. I promised myself that when I turned 40 - "no more all-nighters". My last all-nighter was when I was 52. MEETINGS / STANDING MEETINGS Meetings are the biggest time-wasting invention of all time. I have caused at least a few man-years of wasted time with my meetings. Standing meetings should be outlawed. Standing meetings always degenerate into a waste of time. An email is usually more than adequate. When it is easier to call a meeting than to write the email, you are really out of control. Always have a unique agenda to make sure you know what you want to accomplish. Don't copy the agenda from the last meeting. Start from scratch. If the purpose of the meeting is to make comments, send an email. If you want input, send an email. If you want a decision, send out a poll. Just make sure you need to meet to get the result that you need. EFFICIENCY VS EFFECTIVENESS Efficiency and effectiveness are not the same thing. You want effectiveness every time. Some people can get tons of stuff done every day. They burn through the mail, the email, setting up meetings, making decisions, completing assignments. It is possible that they were 100% efficient in the use of their time. If none of this work led to accomplishing their top priorities, then they were 0% effective. Racing to the finish line only counts if you are in the right race. DAILY GOALS The best technique that I have found for staying effective is the 3 Daily Goals. End each day by evaluating what you accomplished toward your 3 Daily Goals. Then write down the 3 Daily Goals you want to accomplish the next day to take you closer to meeting your top priorities. During the day, check the list every hour or so. Get back on track if needed. PRIORITIES I can't tell you what your priorities should be, but I can tell you how to prioritize your design work.

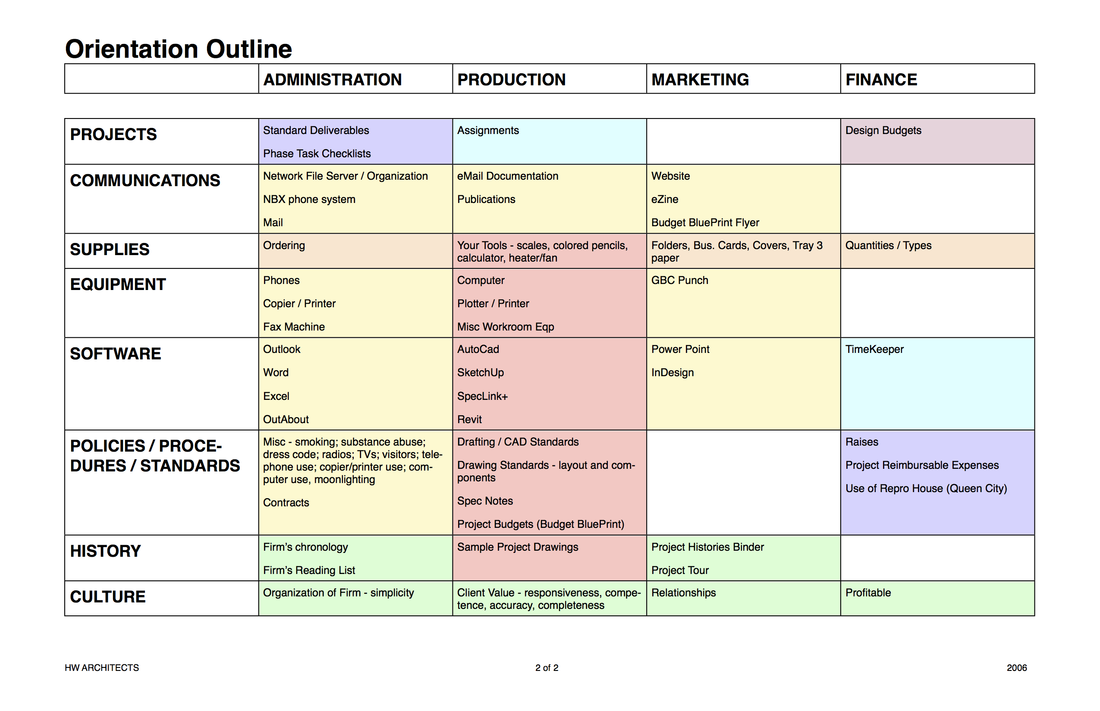

When a new person comes on board, you need to show them the ropes (or be shown the ropes). We used this downloadable matrix for years to guide that orientation. The point was not to drag it out, but to be thorough, which we thought was to everyone's benefit. The terms shown here may not be meaningful to you, but whatever you think it means will do nicely. However, I will define the column and row headings since they are the crux of the tool. COLUMNS

ROWS

Each color represents a different orientation session led by the most appropriate person. The goal is to cover everything during the first two weeks. We found that if it takes much longer, it rarely is completed. BLUE takes place the first day. Followed on subsequent days by YELLOW, DARK ORANGE, PINK (includes Design Budgets - LIGHT BROWN), LIGHT ORANGE, GREEN, LAVENDER. It is fairly common to edit the matrix to suit the person being oriented - some things do not apply to everyone. If you are a new-hire, you might find that your new firm doesn't do anything like this. In which case, take it upon yourself to ask, “I was wondering about...” until you run out of questions. originally posted - OCT 2012 This is the third post in a series that addresses design aspects of stairs. The earlier two posts can be found here and were called Commercial Stair Layouts - Rule Of Thumb and Stair Technical Considerations - Rule Of Thumb. These form the basis for jumping into finish considerations.

Finish Considerations When I am working out a stair configuration and basic structural considerations, I find that is it helpful to have a concept of what I want the final stair to look like. This might take a half hour longer during the early design, but it can save you hours of changes later. There are four components of a stair that need consideration - Stringers, Hand Rails, Guards, Treads/Risers. Stringers The reasons that you might consider one material instead of another was covered in the 'Technical Rule Of Thumb' noted above. 99% of the time I use steel for the stringers. If I want the stair to be a focal point or a design feature, I discard the usual channel stringer solution and start to consider using a plate, a tube or a pair of boxed channels. I like the way these structural shapes look. You will need to get your structural engineer involved at some point, but there are lots of ways to get the look you want by varying the structural characteristics of the steel stringer. For instance, a standard 12" steel channel could be doubled up to form a crisp box shape about 3" x 12". Usually getting the shape you want "overdoes" the structural capacity, as long as you stay close to a 12" depth or more. This same stringer could also be a 2" or 3" x 12" tube or a 1-3/4" x 12" box shape formed by welding a plate to close the open side of a channel. Or keep it really simple with a 3/4" x 12" plate. In all these solutions a key to looking good is to remove (grind off) all mill marks, grind welds smooth, and fill any joints by continuous welding or by using body filler. Hand Rails Code has lots to say about hand rails, limiting diameter, shape and clearances. Hand rails can be wood, steel, aluminum, stainless steel, or nylon-covered metal. I think wood looks a bit out of place unless your building has a lot of wood trim elsewhere. Steel needs to be painted and the paint rarely stays intact for more than a month. I tend to use a lot of anodized aluminum for hand rails with a hairline jointing system. Stainless steel usually costs more and is harder to get and keep a good finish on. Nylon-covered metal is fairly expensive, but it is the only way to realistically introduce color. I don't like to leave the hand rail mounting brackets up to the contractor's discretion. The wrong brackets will "kill" a lot of design effort. Guards Guards are another item that the code controls by dictating configuration: height, strength, openness, climb-ability. The choices are pickets, screens, panels, glass, and solid. Before the latest International Building Code was released, which I haven't reviewed yet, the non-climb-ability provision eliminated everyone's favorite solutions - the horizontal rails, cables. This eliminated a lot of descent-looking solutions that weren't terribly expensive. You are left with pickets at 4" on center or jump right into some fairly expensive screens or panels. The screens are made of wire or expanded metal lathe in frames that are made to the sizes needed to fill the guard openings between posts and rails. Panels are similar except mostly solid and made from wood, composites or sheet metal. The next big jump in cost is to glass. The tempered glass is expensive, and some of the stainless steel posts can take your breath away. Of course you can always put your own system together using epoxy painted steel posts and standard fittings to hold the glass. Unfortunately this usually shifts the cost out of construction and into design where you might not be compensated for your effort to save money. Solid guards are a low-cost solution. You need a steel framework into which to set metal studs and drywall. This solution works best when you can create an interesting shape out of the stair or you just want something without the curse of pickets. Treads/Risers The typical commercial stair has treads and risers made of concrete-filled steel pans. Code may also dictate 'closed' risers. How to dress this up? Rubber and vinyl are the only products that I can think of that are designed to solve this issue. Unfortunately, they don't really offer an up-graded appearance. They are the 'picket-solution' of tread finishes. Carpet is the old standby and works well. Wood, stone, tile, and other floor finishes need some careful attention. The leading edge of the tread is very susceptible to impact damage or becoming a tripping hazard. Another issue is that a flooring over 1/4" in thickness starts to impact the stair configuration itself and may need adjusted riser heights at the top and bottom. That said, a 1" stone tread is well worth the attention to detail. If you have gotten this far, you probably fall into one of two camps. First, those folks who can't wait to get their hands on the next stair design. Second, those folks who are sure they don't want to design a stair. I like stair design. It is like a mini-project with all the same considerations as a building without the pesky need to integrate the M/E disciplines. |

x

Archives

February 2024

Categories

All

|

Architekwiki | Architect's Resource | Greater Cincinnati

© 2012-2022 Architekwiki

© 2012-2022 Architekwiki