|

I've been working on a series of articles about designing stairs. There isn’t any special order to them. The first one was Commercial Stair Layouts Rule Of Thumb about a month ago.

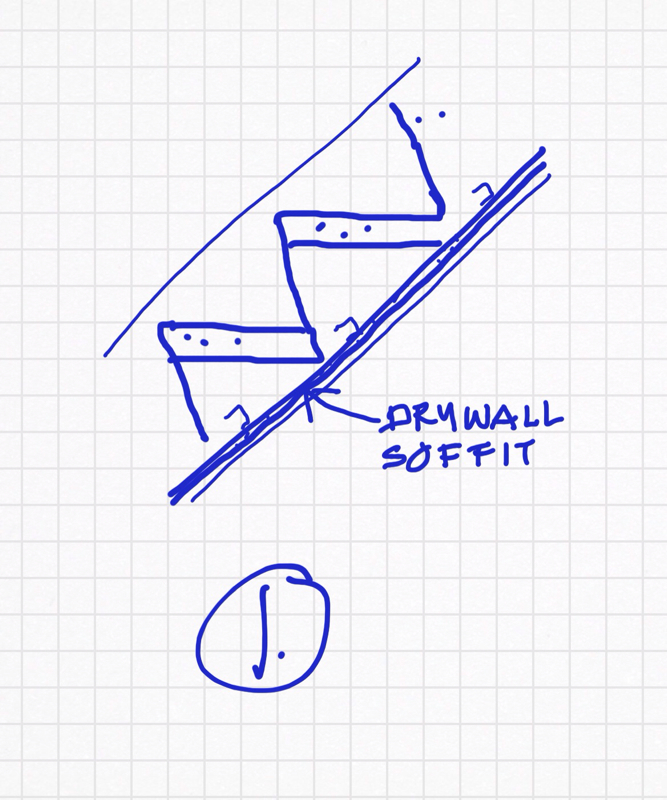

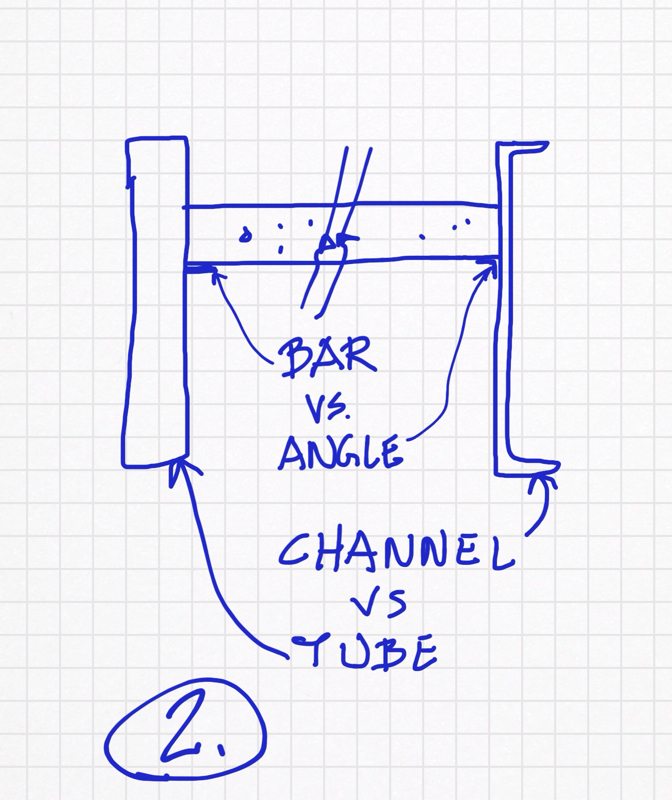

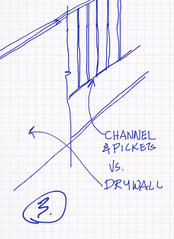

The technical considerations I’m talking about are selection of materials, and structural detailing. Here is how I usually proceed. The vast majority of buildings we have designed are Type 2B, which back in the day was known as “unprotected non-combustible”. That ’non-combustible’ part all-but-eliminates wood stairs. But other issues that work against wood are the width of stair required in non-residential buildings and the difficulty of joining the members structurally. It may sound odd but it is much simpler to build a steel stair. The standard joining methods scale up very nicely in steel; not so much with wood. This leads to not only more difficulty designing the stair but also building it. The perceived savings by using wood quickly disappears. We can dispatch concrete stairs by simply saying they work great, easy to design and, unfortunately, require lots of skilled carpentry labor to construct. This prices them out of reach for most budgets. Steel is the workhorse when it comes to commercial stairs. You see them everywhere - confirmation of their fitness. You may have also noticed that they can be ugly. The typical exit stair is made from channel stringers, a concrete-filled sheet metal pan resting on angles fastened to the stringers. The railings are steel pipes with steel bar pickets at 4" o.c. It can get rough. But there are several things you can do to improve the looks. These are simple and well worth the effort and cost if the stair isn’t completely utilitarian.

A couple of other tricks that improve the appearance of stairs are: a) adding a little width to make a more gracious appearance; b) holding the descending riser back one tread on a switchback stair so the handrail can make a smooth transition; c) splay the stringer(s) at the bottom for a spartan version of a Renaissance flowing stair; d) use the strength and workability of the steel stringers to ’suspend’ and display the stair. Once you are conversant with the detailing and code limitations, push the limits. If you are ever in Las Vegas, check out the stairs in the high-end shopping venues to see how you can make the stair into an art object! Sounds like tax-deductible research to me. Stair Finishes are considered here. Hard Walls - The Traditional Office

The traditional office supports the top-down way of working. The private office is recognized as a status symbol and it is the best at providing personal territory. Hard-walled offices have some advantages that, if needed, are difficult to duplicate with cubicles, let alone open plan offices. A hard-walled office is more secure and it can provide the best visual and acoustic privacy. It is the ideal space when concentration is required or when sensitive conversations take place. The traditional office is usually more expensive to create even if the building space already exists because of the individual wiring, lighting and HVAC. A private office can provide superior day-lighting for the occupant, but sharing access to windows presents a challenge. Cubicle - The New Office Thanks to Dilbert and the uninspired use by large corporations, cubicles have a bad reputation. Even so cubicles have several advantages; and, when implemented with care, they can even be a superior workspace. In general cubicles support team, project and collaborative ways of working. This is their strength. Cubicles can be customized to the person and the job in ways that aren't usually feasible in a traditional office. For instance it is very easy to have twice as much work surface at your fingertips. Drawers and shelves can also be located for convenience in the type and quantity needed. The amount of and height of enclosure can vary to support the degree of interaction or isolation that is desired. For the organization there are several benefits as well. Cubicles can be reconfigured quickly without mess and without changing lighting and air conditioning. Cubicles can be depreciated more quickly and can be re-used over and over. They can house an employee in a better work environment in 2/3 the area of an office. Cubicles have a lower life- cycle cost. Our first Herman Miller Action Office cubicle components were purchased 30 years ago and are still providing service. They have been reconfigured at least every five years and enhanced with new and refurbished pieces where needed. A 100 SF cubicle provides a much nicer work environment than the same size traditional hard walled office. Hybrid Usually the best solution is not an either/or proposition, but a mix of hard walls and cubicles. The ideal solution is to select the best type of work space for each individual and the job they perform. An oversized hard wall office used to house a group, in traditional furniture, cubicles, or a mix encourages a team approach and provides some of the benefits of hard walls along with those of the cubicle. My personal preference: a large cubicle. But I am also quite fond of an informal home office. Back in the mid-1990s we held a charrette to help a client comply with the parent company’s desire to be sustainable. We brainstormed all the ways that could contribute to that goal. Out of a list of 20+, we found that a few were surprisingly easy - recycling steel and drywall. We found a few were not legal or could not get approval in a reasonable timeframe, if at all - composting toilets, gray water re-use. We found that a geothermal system using an on-site pond was more energy-efficient than any other alternative. Through energy modeling we found out how valuable day-lighting was, and how the occupants’ connected load could undermine a lot of other goals. We set about implementing all the initiatives that were feasible; and especially concentrated on the three best tactics for saving energy - geothermal heating and cooling, day-lighting and reduced connected load. GEOTHERMAL HVAC is usually the main energy use in a building. Although a geothermal system has higher first costs, the energy consumed is reduced by mechanical advantage to the smallest amount for the same results. Often the first costs are paid back through reduced energy costs in three to ten years or less. Government subsidies (through 2016) figure into the calculation nowadays. We maxed out the pond capacity, and used a geothermal heat pump system for the 27,000 SF of offices. The extra pond capacity not needed for the offices was used in the plant for process heating. DAY-LIGHTING Artificial lighting is the second highest energy cost in commercial buildings. Day-lighting can reduce the use significantly, and has an additional bonus. Artificial lighting creates heat, which requires more air conditioning. So you save even more from day-lighting than just by not using lights. Energy use in commercial buildings over 10,000 SF is driven by what goes on inside rather than the envelope. House are the opposite. This has the curious result that commercial buildings are cooled nearly all year around. So the cooling savings from day-lighting is significant and not offset by a need for winter heating. This recent post on day-lighting is a roof monitor system used to light all new common spaces. Existing corridors were skylighted with frosted borrowed lights bringing the daylight into adjoining spaces. The pictures below show two day-lighting tactics that were used. Note the 'Sunbenders' to capture the maximum sunlight most of the year while providing some shading in summer months. Also visible are the PV panels used as window overhangs. The PVs powered the phone computer systems. REDUCED CONNECTED LOAD

This is just a way of saying to use less power hungry devices. Some things to avoid:

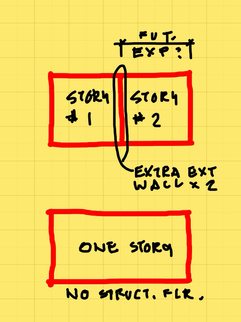

SUMMARY All three of these initiatives have a payback, and make a building more valuable in an enduring way that bicycle racks and public transport access do not (but, that's a rant for another day). Your client will love you for minimizing his/her carbon footprint and cost of operation, whether you try for LEED certification or not. Epilogue The building we designed passed to a new owner when our client’s business was purchased. Alas, the new owner wasn't interested in the building’s ’Green Pedigree’. You may have noticed that I have a poll running. Take a sec and vote. Polldaddy is embedded in Weeby and is pretty easy to use. I think the actual free Polldaddy account is even easier, and it has the benefit of offering a few more features - like quizzes! Take my Masonry Expert Quiz below to learn a bit about masonry and see how Polldaddy works/looks. BTW there are several themes/color schemes for your polls, surveys and quizzes. How did you do? When you are starting the design of a new stand-alone building, a number of considerations come up that don't enter the picture for a remodeling or renovation. A major one: How many stories? More stories may allow more overall area or allow space for future expansion. A basement may also be a consideration. More Floors? Additional floors for your building can offer several advantages:

There is one final way in which costs increase because of additional floors - incidental features. The incidental features are stairs and, most likely, elevator and toilet rooms. Besides the cost of these features, they will either displace useable square footage or cause you to increase the overall size of your building.

Another consideration is the area of each story. Stories that are less than 10,000 SF are not as efficient because of the higher percentage of floor area given over to ’core’ functions. So multiple floors can work against you in this way too. Most of the time the advantages of additional floors are well worth the additional cost, but additional floors are inherently more expensive. This article has a more detailed analysis. What About A Basement? Basements are a special case when it comes to stories. Even though the same issues apply as discussed above, basements cost less than upper floors of a building. This is due to the lower cost of the exterior walls, lack of windows, and (usually) more Spartan finishes. Basements may make sense because of sloping land or the need for significant space for storage and building equipment. If this is the case, a basement will save money overall because the cost per square foot of basement space will be 20% to 40% less than upper stories. However, basements are not free. If the basement space is not really needed, it will increase overall costs. Perhaps the idea is to use the basement when you need more space. But a basement will not be as flexible or as suitable for many needs when that time comes. For a more in-depth analysis, see this article. An alternative strategy to consider for expansion is unfinished upper floor space. Unfinished upper floor space will cost more than a basement but it will be much more flexible in how you can use it. And significantly cheaper than an addition. Green Hot Water Heaters

Hot water heaters, as we know them, are quickly becoming a thing of the past. The main change is the elimination of the tank and locating the heater near the need for hot water. The benefits are less hot water piping, less energy used because you don't keep a tank of water hot at all times, an endless supply of hot water when needed, and half the maintenance cost for the system. It is not uncommon for the annual cost of hot water to be 50% or less using this system. This style of tankless hot water heater is suitable for residential and commercial uses and for new or replacement / retrofit. Here is how the system works. Instead of a tank of water kept hot in case you need it, you have what amounts to a mini-boiler ready to spring into action when needed. A tankless hot water heater can provide 5 to 10 gallons of 120 degree water per minute - and can keep it up for as long as needed. These systems are green in several ways. First is the energy savings from only heating the water you use. Second is the savings in materials - the piping, the elimination of the tank, and the replacement of the heater every 20 years instead of 7 (unless you are luckier than I am). Economically, it is an easy sell. Although the initial cost is roughly twice the cost of a natural gas hot water heater. The savings will make this a break-even in 4 to 5 years. Over its 20 year life expectancy, this system will cost less than half of the cost of the tank system. The limitations are: 1) you need natural gas*; 2) the units must be vented; 3) the units are most effective if they are close to the hot water usage; 4) if you need a really large quantity of hot water in a short time, say showering the football team in fifteen minutes, then this isn't the way to go. Rinnai, one of the popular brands has a helpful website at http://www.rinnai.us/tankless-water-heater Another resource comparing several brands is Household Water Systems. You can find links to pricing here. * My understanding is that natural gas is more economical to operate, but electric tankless water heaters are available. |

x

Archives

February 2024

Categories

All

|

Architekwiki | Architect's Resource | Greater Cincinnati

© 2012-2022 Architekwiki

© 2012-2022 Architekwiki