|

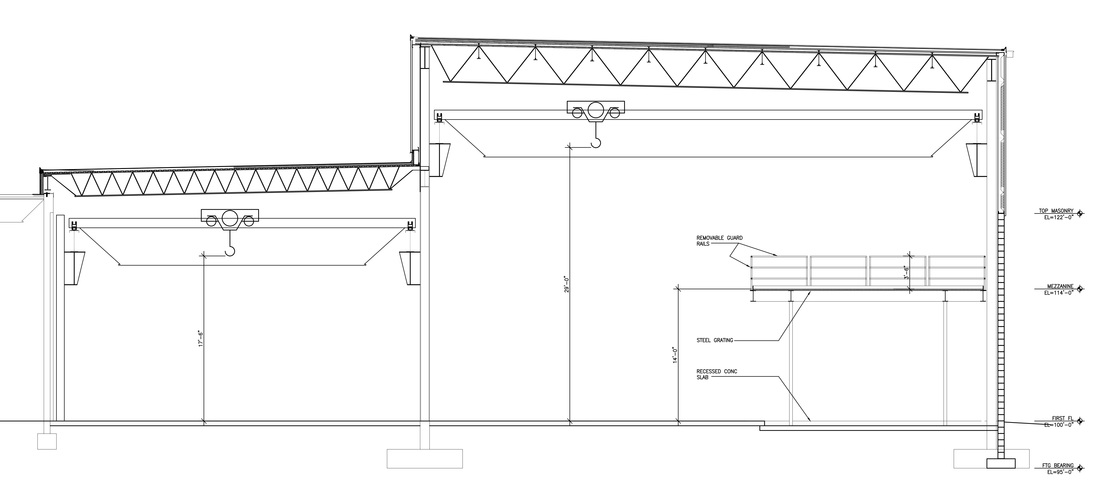

The most common type of crane that we have dealt with is a bridge crane. These cranes have spanned bays as wide as 80' and had hoists rated for lifting 20 tons. A 35' (or taller) building is often needed in these circumstances. These cranes travel most, if not all, of the length of a bay of a building, the crane bay. The main components of a crane assembly are: footings, columns, crane beams, crane rails (like railroad rails only lighter weight), crane bridge, truck, and hoist. Each of these components has its own considerations. The columns - often separate columns are used to isolate vibrations and bending caused by crane beam brackets. X-Bracing may be required. Structural capacity of crane beams needs to limit sag and camber can be a problem too. Either can stress the trolley carrying the end of the bridge and in extreme cases causing it to become stuck. Welding the crane rails to the crane beams is not desirable for long crane spans or heavy cranes. J-Bolts seem to work best and are easy to adjust. OSHA has clearance requirements at ends of the bridge span and above the truck and hoist. Electrification of the crane is accomplished by festooned cable or buss bar. The electrician supplies power to a point along the crane beam for hookup by the crane erector. Height to the crane lifting hook is the vertical criteria around which clearances and structure are worked out. Clear span or horizontal travel of the hook determines the width of the bay or building. It is rare that the hook needs to get to the edge of the specified clear width. Take care with roof drains, exh ducts, or plumbing vents that there is a path for each of them that respects the required clearances. Often lighting levels need to be high in a crane bay used for assembly work. The vertical clearance can make this a challenge. Consider portable floor set mobile lighting. It may provide better light where needed rather than trying to light the entire crane bay to 70 fc. If feasible this could reduce energy use and provide better lighting. Get the Owner's crane supplier tied down early so coordination doesn't cause construction delays and extras. Not all cranes can fit as intended if the building design is determined without the crane specs. Comments are closed.

|

x

Archives

February 2024

Categories

All

|

Architekwiki | Architect's Resource | Greater Cincinnati

© 2012-2022 Architekwiki

© 2012-2022 Architekwiki